Blog

How Couplings Are Used for Water & Sewer Line Pipe Repair

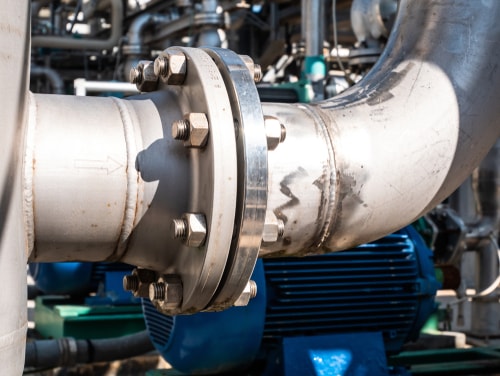

Pipe couplings play an important role in repairing water and sewer piping systems. Due to the fact that couplings offer a fast method for connecting pipes of all sizes and materials, they can be used in virtually any pipe joining conditions, from cooling return pipes in power plants to gas and water supply systems.

Whether you are looking for a suitable pipe coupling for water and wastewater systems in Rochester or anywhere else in the country, you should learn as much as you can about the different coupling types as well as their specific applications in the industry. Read on.

How does a pipe coupling work?

In water and wastewater piping systems, pipe couplings are used to connect two or more sections of pipe with the aim of maintaining continuity between them. They can be used to join pipes of different or equal sizes, as well as connect more than just two pipes if they are cross or T-shaped.

Flexible couplings allow for efficient and speedy piping repair. This is especially important when repairing municipal water and sewer lines since prolonged service interruptions are usually not permissible. There are numerous different types of couplings used in the water and wastewater industry, providing an economical and effective means of joining various pipe materials and sizes.

How do you use a pipe coupling?

There is no single method for using pipe couplings in water and wastewater settings. This is because different piping repair or replacement projects involve the use of different types of pipe repair clamps or couplings which may have specific installation requirements. In general, pipe couplings can be used for:

- Connecting pre-fabricated pipe systems: couplings can be used to connect a wide range of pre-manufactured pipes. Some couplings are designed to join pipe sections of the same O.D. diameters, whereas others can be modified to a number of different pipe sizes.

- Performing fast piping modifications: in many circumstances, using a pipe coupling or connector is the most efficient and economical way to modify or replace pipe sections in water and wastewater systems.

- Connecting pipe sections of different materials: pipe couplings are generally made from similar or identical materials as that of the tube or pipe to be joined. For instance, copper couplings would be used for copper pipes, although brass and bronze are also common.

- Performing reliable and quick piping repairs: in many cases, couplings offer the most economical solution for repairing leaky, damaged, or deteriorated piping. This is especially true if the deterioration is extensive and replacing the damaged section of pipe is the most viable option.

When using couplings for pipe repair, it is also important to consider the internal pressure and axial stresses present in the pipework. The axial loadings or stresses have to be locally restrained during the repair procedure in order to prevent the pipe components from separating.

Where is plumbing rubber coupling used?

While a plumbing rubber coupling can be used for any of the aforementioned applications, they are primarily used to connect two sections of the pipe together in drainage, wastewater, or ventilation systems, either as a permanent or a temporary solution.

Their flexibility and adaptability make them especially effective at joining pipes made of different materials (e.g. PVC to cast iron, HDPE to steel, etc.), as well as connecting pipes with slight diameter variations.

For these reasons, rubber plumbing couplings are commonly found in sewer and (underground) drainage infrastructures, as well as in systems where slight movements may occur, primarily due to soil shifting.

What is a drain coupling?

This simple, yet effective design and incredible ease of installation make drain pipe couplings a popular choice for a wide variety of applications, including drainage systems for sinks, showers, bathtubs, toilets, and a whole host of other fixtures.

What is the advantage of rubber coupling?

We already mentioned many features that make rubber plumbing couplings stand out among similar fittings. Now, it’s time to see how those features give them an advantage over their rigid counterparts:

- Flexibility: Quality rubber drain pipe couplings are made out of allows for slight movements, shifts, or contractions of the conjoined pipes – without risking leaks.

- Versatility: The rubber’s ability to accommodate different materials and pipe sizes makes it applicable in a wide variety of projects and settings.

- Vibration absorption: In settings where vibrations may occur (e.g. HVAC, high rise plumbing, industrial plumbing, etc.), the rubber’s natural ability to absorb shocks provides a safeguard against piping becoming misaligned or cracking at the joints.

- Installation ease: Rubber pipe couplings are incredibly easy to install, as they do not require any specialized equipment or methods, making them an excellent choice in standard and emergency situations.

- Durability: Resistance to corrosion, chemicals, elements, and temperature variations (to a degree) makes rubber fittings long-lasting even in harsh environmental conditions.

How long do plumbing rubber couplings last?

The average lifespan of a plumbing rubber coupling depends on the quality of the materials, conditions of use, and environmental factors, and can range anywhere from several years to several decades. As it stands, this is a massive discrepancy, so it demands a bit more clarification.

As an example, standard low-cost low-quality plumbing rubber couplings that can be bought in any hardware store by a bucketload have a nominal lifespan of 5 – 10 years. They are acceptable as a temporary fix only.

However, if the issue requires a more permanent solution, then going for top-quality drain pipe couplings, such as Fernco or Smith-Blair, is the only feasible choice. These (and similar) manufacturers create fittings that can easily last upwards of 50 years – with regular, everyday use and minimal maintenance.

Do flexible couplings meet code?

In short, yes – flexible drain pipe couplings generally do meet plumbing codes, especially if they’re made by a recognized manufacturer. However, different coupling types are intended for different applications and, therefore, may be subject to slightly different local code requirements.

As such, it is important to ensure that the fitting is specifically rated for its intended use. This is typically denoted with a certification by the relevant organizations (e.g. American Society for Testing and Materials (ASTM)). Still, it is always advisable to verify compliance with the relevant local authorities prior to installation, just to be on the safe side and avoid future issues.

Looking for a durable pipe coupling in Rochester or across the nation?

At Blair Supply Corp, we carry high-quality piping repair materials, including top-of-the-line drain pipe couplings and plumbing rubber couplings, for a wide range of applications. In fact, we are the leading supplier in the utility distribution industry, offering everything from heavy-duty water mains tools to sturdy clamps for industrial water pipe repair. We carry products from a great number of reputable suppliers, including Fernco, Krausz, Smith-Blair, Integrity Fusion, and more.

You can count on us no matter your location since we ship water and wastewater industry materials nationwide from our warehouse near Greater Rochester International Airport as well as from our other two warehouses in Avoca, and Watertown. Browse our online offer or give us a call today!