Blog

How Couplings Are Used for Water & Sewer Line Pipe Repair

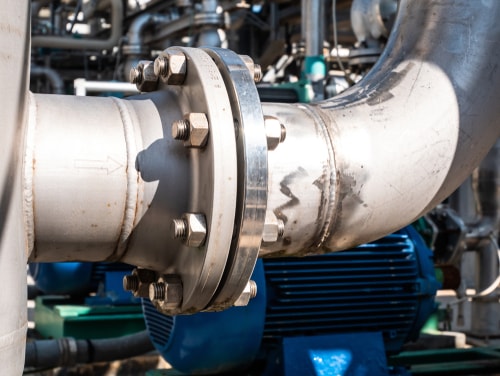

Pipe couplings play an important role in repairing water and sewer piping systems. Due to the fact that couplings offer a fast method for connecting pipes of all sizes and materials, they can be used in virtually any pipe joining conditions, from cooling return pipes in power plants to gas and water supply systems.

Whether you are looking for a suitable pipe coupling for water and wastewater systems in Rochester or anywhere else in the country, you should learn as much as you can about the different coupling types as well as their specific applications in the industry. Read on.

How does a pipe coupling work?

In water and wastewater piping systems, pipe couplings are used to connect two or more sections of pipe with the aim of maintaining continuity between them. They can be used to join pipes of different or equal sizes, as well as connect more than just two pipes if they are cross or T-shaped.

Flexible couplings allow for efficient and speedy piping repair. This is especially important when repairing municipal water and sewer lines since prolonged service interruptions are usually not permissible. There are numerous different types of couplings used in the water and wastewater industry, providing an economical and effective means of joining various pipe materials and sizes.

How do you use a pipe coupling?

There is no single method for using pipe couplings in water and wastewater settings. This is because different piping repair or replacement projects involve the use of different types of pipe repair clamps or couplings which may have specific installation requirements. In general, pipe couplings can be used for:

- Connecting pre-fabricated pipe systems: couplings can be used to connect a wide range of pre-manufactured pipes. Some couplings are designed to join pipe sections of the same O.D. diameters, whereas others can be modified to a number of different pipe sizes.

- Performing fast piping modifications: in many circumstances, using a pipe coupling or connector is the most efficient and economical way to modify or replace pipe sections in water and wastewater systems.

- Connecting pipe sections of different materials: pipe couplings are generally made from similar or identical materials as that of the tube or pipe to be joined. For instance, copper couplings would be used for copper pipes, although brass and bronze are also common.

- Performing reliable and quick piping repairs: in many cases, couplings offer the most economical solution for repairing leaky, damaged, or deteriorated piping. This especially true if the deterioration is extensive and replacing the damaged section of pipe is the most viable option.

When using couplings for pipe repair, it is also important to consider the internal pressure and axial stresses present in the pipework. The axial loadings or stresses have to be locally restrained during the repair procedure in order to prevent the pipe components from separating.

Looking for a durable pipe coupling in Rochester or across the nation?

You can count on us no matter your location, since we ship water and wastewater industry materials nationwide from our warehouse near Greater Rochester International Airport as well as from our other two warehouses in Avoca, and Watertown. Browse our online offer or give us a call today!