Blog

Choosing the Right Pipe Repair Coupling

Maintaining and repairing piping systems, especially industrial and commercial ones, is an undertaking that leaves little to no room for error. As such, selecting the right piper repair coupling is of utmost importance, as this component is key to ensuring the integrity and longevity of the pipeline while minimizing costly downtime.

However, with so many options available today, how can you be sure you’ve made the right choice? Let’s delve into the key considerations for choosing the ideal piece of hardware for your project, as well as explore the merits of the world-renowned Smith-Blair coupling.

How do I choose a coupling?

Selecting the appropriate pipe repair coupling requires careful consideration of various factors, with the crucial ones being:

- Pipe material & size: Identify the material and size of the pipes that need repair. Different coupling designs are suitable for specific materials, such as steel, ductile iron, PVC, or HDPE. Additionally, ensure that the coupling is compatible with the pipe’s outer diameter and wall thickness.

- Pressure & temperature ratings: Determine the maximum pressure and temperature the coupling will need to withstand. It’s crucial to choose a component that can handle the anticipated working conditions to prevent failures or leaks.

- Installation method: Consider the ease and convenience of installation. Some couplings require special tools or welding, while others offer quick and straightforward installation, reducing downtime during repairs.

- Corrosion resistance: Evaluate the environment in which the piping system operates. If corrosion is a concern, opt for couplings made from corrosion-resistant materials or, at least, coated with protective layers to ensure long-term durability.

- Certification & Compliance: Check if the coupling meets industry standards and certifications, such as those from organizations like the American Water Works Association (AWWA) or the International Organization for Standardization (ISO). Compliant couplings are more likely to provide reliable performance, as well as meet safety regulations.

Which type of coupling is best?

When it comes to couplings, there’s no “one size fits all” solution. Rather, the best choice will be dependent on the requirements of your project. That said, there are several coupling types available, each suited for a specific application. Here are some commonly used types and their key characteristics:

- Compression couplings are versatile and easy to install. They utilize rubber or synthetic gaskets to create a watertight seal and can accommodate slight pipe misalignments. As such, they’re ideal for low to moderate-pressure applications.

- Flanged couplings consist of two flanges, one on each pipe end, connected by bolts and gaskets. They offer excellent strength and durability, making them suitable for high-pressure and high-temperature applications. However, they require precise alignment and a more involved installation process.

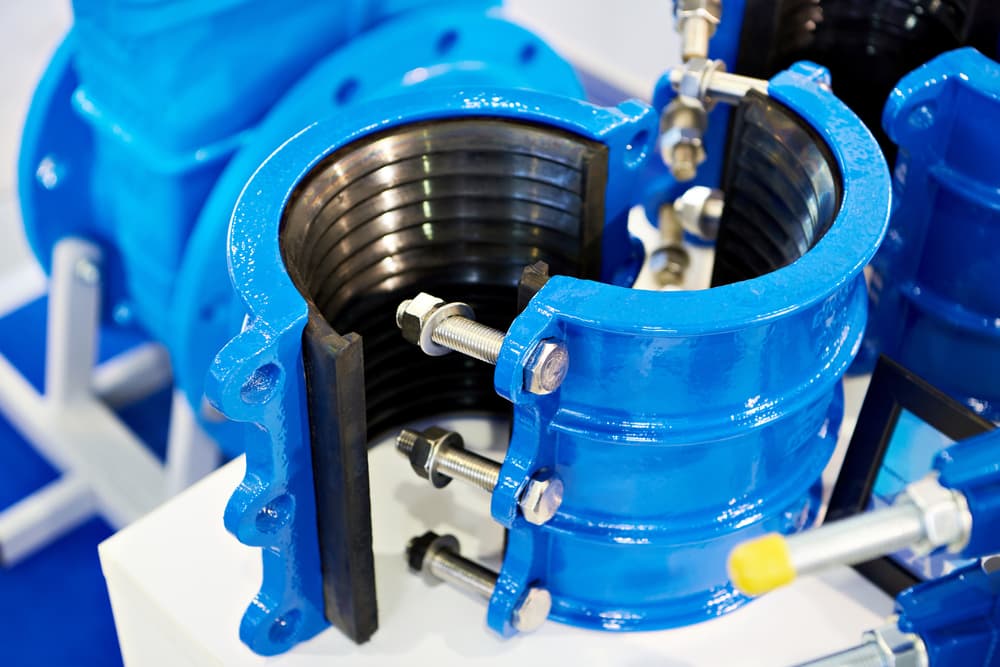

- Mechanical couplings utilize implements such as bolts, clamps, or bands to secure the pipes together. They provide a robust and reliable connection and are often used in industrial settings where high pressures and mechanical stresses are present.

- Flexible couplings accommodate pipe movements, vibrations, or thermal expansions and contractions. They are suitable for applications where the pipes are subject to shifting or where flexibility is necessary to prevent stress-related failures.

What is a Smith-Blair coupling?

A widely recognized and trusted name in the field of pipe repair, Smith-Blair components are renowned for their quality and reliability, making them the go-to choice for industrial users throughout the US and beyond.

These couplings feature a sturdy construction that can withstand high pressures and harsh environmental conditions. Additionally, Smith-Blair pipe repair parts utilize a variety of sealing methods (including compression gaskets) to ensure leak-free connections.

They offer excellent flexibility and can handle pipe misalignment, making installation easier and more forgiving. Finally, every piece of hardware undergoes rigorous testing to meet industry standards and certifications, guaranteeing their performance and reliability.

Where in New York State can I find a Smith-Blair coupling that will perfectly suit my needs?

For more than 60 years, Blair Supply Corp. remains the premier provider of top-quality components and materials for water main, utility/construction, sewer/drainage, and highway applications, serving thousands of satisfied customers throughout the State of New York.

With our extensive experience and expertise in the industry, our ability to come up with the perfect solution to meet your exact needs is unparalleled. Reach out to our Rochester or Watertown warehouses today and discover the reliability that comes with having top-of-the-line materials at all times!