Sewer & Drainage Materials: Hard-Wearing Culvert Pipes for Sale

Start Shopping Our Online Product Store Now

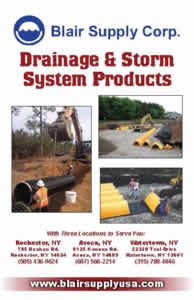

Modern sewage collection systems require pipes designed for strength and longevity. At Blair Supply Corp, we carry a wide array of corrugated and culvert pipes of all shapes and sizes, built to maximize the sewer system capacity and minimize the possibility of damage. At our Avoca, Watertown, and Rochester warehouses, you can get top-brand sewer pipes for all industrial applications. Check out our online selection and feel free to contact us if you have any questions.

Sewer & Drainage Materials

Blair Supply Corp: your trusted provider of culvert pipes and more

As a proud member of the leading industry organizations and associations, such as the American Water Works Association, WASDA, and others, we are known for providing our customers with high-quality water industry materials. Our transparent and dedicated approach also sets us apart and guarantees the loyalty and trust of our customers.

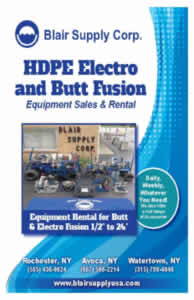

Our selection of sewer system materials includes everything from HDPE, PVC, and ductile iron pipes to versatile fittings and manhole castings. All materials and products in our range are hard-wearing, durable, and reliable, fit for numerous industrial applications.

In simple terms, a culvert can be defined as a tunnel that is constructed under a roadway or railway in order to transport electrical cables or provide cross drainage. Culvert pipes come in various shapes and designs that depend on factors such as roadway height, the elevation of the water surface, and hydraulic conditions. At our warehouses in Avoca, Rochester, and Watertown, we carry culverts of all makes and models. The most important culvert types include:

Pipe culverts

Owing to their affordable pricing and relatively easy installation, pipe culverts are by far the most popular option today. They come in various shapes (elliptical, circular, pipe arch) and can be used either individually or in combination with multiple culverts in case of larger flows.

Box culverts

Another popular option, box culverts feature a concrete floor that allows for smooth water flow. They are typically made from reinforced concrete, creating a rigid frame structure. While box culverts can be great for non-perennial streams, they do have some setbacks. For instance, diversion or dewatering may be necessary for installation, as the culverts need to be installed on a dry surface.

Arch culverts

Arch culverts are lightweight arches suitable for openings of larger but stable waterways. Pipe arches are characterized by a more aesthetically pleasing appearance and are recommended for sites with limited headroom. These culverts are typically made of stone masonry, RCC, or metal and are relatively easy to install.

Bridge culverts

Bridge culverts are exactly what their name indicates: both a culvert and a bridge. They are rectangular and typically constructed on canals and rivers by laying a foundation underground and a pavement surface on top. This multipurpose culvert is constructed to be extremely strong in order to withstand traffic.

Metal box culverts

These culverts also serve a dual purpose but are slightly more economical when compared to the standard bridge culverts. Metal box culverts are low profile and typically manufactured from standard or deep corrugated structural plates. They are the best for sites where there is a need to maintain the existing road grade.

Determining the right culvert pipe size depends on a great number of factors specific to the individual project. In industrial settings, the minimal culvert pipe size should be carefully determined according to state recommendations and regulations in order to ensure the durability and effectiveness of the pipe.

Underground culvert pipes come in a variety of diameters to help construction workers meet structural and hydraulic requirements of each individual project. Culvert pipe diameters range from 6 to 150 and the exact size will vary greatly depending on the specific circumstances and requirements.

The selection process tends to differ significantly between private and public applications. If you are looking for a culvert pipe for sale for your private drainage needs, you will have to get familiar with the most commonly used materials and their individual characteristics. In industrial settings, however, the culvert pipe selection process has to be performed according to the latest industry standards in order to ensure the pipe’s longevity and successfully combat the common culvert deterioration causes.

Different culvert materials react differently to abrasion, physical wear, corrosion, and other deterioration causes. Here’s how the most frequently used culvert materials will hold up to different types of deterioration:

- Metal: culverts made of corrugated metal, aluminum, and galvanized steel are affordable, strong and durable, but have a tendency to corrode or rust over time even if galvanized. Another disadvantage of metal culverts is that they tend to be inflexible and heavy.

- Plastic: plastic is an affordable and versatile alternative to metal. Flexible and lightweight, plastic culvert pipes allow for easy installation and transportation and can be easily cut to match any culvert trench size. One drawback is that plastic culverts can get displaced eventually because of the lightweight and buoyant nature of the plastic.

- Concrete: this culvert material is less popular because of its hefty price and difficulty of transport and installation. Nevertheless, concrete is much more durable than plastic or metal, offering high resistance to corrosion and warping and being able to withstand heavy traffic over the culvert.

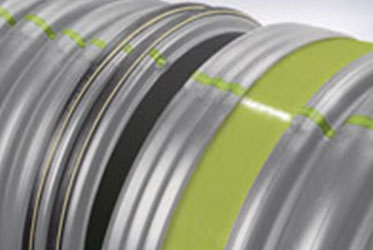

Corrugated pipes have a wide range of applications in diverse settings, including residential, commercial, agricultural, municipal, and industrial (among others). Their build, flexibility, and versatility make them especially suitable for gravity flow management systems, such as stormwater and subsurface drainage, sanitary sewage, or culverts.

Yes, a corrugated pipe can indeed be used for sewer systems. However, it is not the most common first choice, primarily because there are application-specific solutions readily available in Watertown, Rochester, and throughout the NY state. Still, in specific situations where installation constraints are a factor, corrugated pipe can be an excellent choice.

Absolutely! In fact, this is where corrugated pipes truly shine. Their design allows for efficient internal water flow, as well as excess water diversion on the exterior, making corrugated pipes ideal for applications where water management is imperative.

The lifespan of corrugated piping largely depends on three factors:

- Quality of materials used in manufacturing;

- Environmental conditions of installation location;

- Quality and regularity of maintenance.

As an example, a quality corrugated pipe made of high-density polyethylene (HDPE) can easily last up to a century under normal conditions, which is why it’s the most common choice in Rochester and Watertown today.

At Blair Supply Corp, we work closely with the leading industry brands and manufacturers to provide the highest quality of water and wastewater equipment and materials. We have been the leading supplier of drainage and pipe repair materials ever since 1958. You can browse our online store and discover:

- A wide selection of repair clamps and couplings

- Hard-wearing and affordable water service fittings

- Top-quality water meters from Zenner

- Reliable and durable water meter pits

- Industrial-quality water main materials

- Innovative Schonstedt magnetic locators, and more.

Are you looking for a reliable supplier of drainage materials and equipment? You’ve come to the right place. Reach out to Blair Supply Corp. today!